How Innovative Thermoelectrics are Transforming Waste Heat into Sustainable Power

Dr. Gbadebo Taofeek Yusuf, Senior Writer-Academic World

Did you know that over 60% of the energy produced in industrial processes is lost as waste heat? Imagine harnessing that lost energy to power our world sustainably—this is the promise of thermoelectric technology.

Thermoelectric materials, which convert heat into electricity and vice versa, have long held the potential to revolutionize energy efficiency and sustainability. However, their application has historically been limited by challenges such as efficiency, cost, and material availability. Today, with recent advances in material science and a global push for sustainable energy solutions, thermoelectrics are back in the spotlight.This blog explores the future of thermoelectric technology, examining its potential applications across various industries and the innovations that could overcome existing limitations.

Understanding the Basics of Thermoelectrics

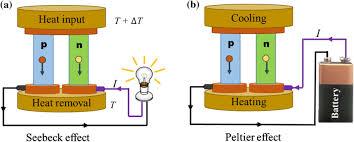

The thermoelectric effect is a fascinating phenomenon where a temperature difference across a material generates an electric voltage. Conversely, an electric current can drive heat from one side to the other. This effect is governed by three primary phenomena.

The image illustrates two thermoelectric effects: the Seebeck effect and the Peltier effect. In part (a), the Seebeck effect is shown, where a temperature difference (ΔT) between two different materials (p-type and n-type semiconductors) generates an electric current, which can be used to power a light bulb. The diagram demonstrates how heat input and removal create this temperature gradient. In part (b), the Peltier effect is depicted, where an electric current supplied by a battery causes heat to be absorbed at one junction and released at the other, resulting in cooling on one side and heating on the other. Both diagrams highlight the dual applications of thermoelectric materials in generating electricity and in heating or cooling devices.

Seebeck Effect: Discovered by Thomas Johann Seebeck in 1821, this effect occurs when two different conductive materials are joined at varying temperatures, generating a voltage proportional to the temperature difference. This principle underpins thermoelectric generators (TEGs).

Peltier Effect: Named after Jean Charles Athanase Peltier, this effect describes the heating or cooling that occurs when an electric current passes through the junction of two different materials. Thermoelectric coolers (TECs) are based on this principle.

Thomson Effect: Discovered by William Thomson (Lord Kelvin), this lesser-known phenomenon refers to the heating or cooling of a homogeneous conductor when an electric current flows through it, depending on the direction of the current relative to the temperature gradient.

The Future of Thermoelectrics: Emerging Applications

1. Waste Heat Recovery in Industry

One of the most promising applications of thermoelectric technology is in waste heat recovery. Significant amounts of energy are lost as waste heat in industries such as manufacturing, power generation, and transportation. Thermoelectric generators (TEGs) can capture this waste heat and convert it into useful electrical energy, improving overall energy efficiency.

The image depicts an industrial facility with large chimneys, representing a power plant or manufacturing site. Such facilities often produce substantial waste heat during energy production or industrial processes. This waste heat can be harnessed using thermoelectric materials, which convert temperature differences directly into electrical energy. The unused heat can be converted into electricity by integrating thermoelectric generators into these facilities thereby improving overall energy efficiency, reducing emissions, and contributing to sustainable energy practices.

Manufacturing Plants: Many industrial processes, such as steelmaking, glass production, and chemical processing, generate large amounts of waste heat. By integrating TEGs into these processes, this heat can be harnessed to reduce energy consumption, potentially leading to significant cost savings and reduced greenhouse gas emissions.

Automotive Industry: Modern vehicles, especially those with internal combustion engines, lose a significant portion of fuel energy as heat. Integrating TEGs into vehicle exhaust systems can convert this waste heat into electricity, which can be used to power onboard electronics or recharge the battery in hybrid and electric vehicles. This innovation could lead to improved fuel efficiency and reduced emissions.

Power Plants: Thermoelectric technology can also be applied in power plants, particularly in fossil fuel and nuclear plants, where substantial heat is lost during the generation process. By capturing this waste heat, power plants can enhance efficiency and reduce the environmental impact of energy production.

2. Thermoelectric Cooling and Heating

Thermoelectric coolers (TECs) offer an innovative alternative to traditional refrigeration and air conditioning systems. Unlike conventional systems that rely on refrigerants and compressors, TECs are solid-state devices with no moving parts, making them more reliable, compact, and environmentally friendly.

The image shows a thermoelectric module, specifically a Peltier cooler, identified by the model number TEC1-12706. This device consists of a ceramic plate with two wires (one red and one black) for electrical connections, which are used to power the module. When an electric current passes through the module, it creates a temperature difference between its two sides—one side becomes hot while the other becomes cold—demonstrating the Peltier effect. Such modules are commonly used in a variety of applications, including electronic cooling systems, portable refrigerators, and climate control seats in vehicles. The compact size and efficiency of these devices make them ideal for applications requiring precise temperature management.

Refrigeration: TECs can be used in refrigerators, freezers, and portable coolers, providing a quieter and more compact solution than traditional refrigeration systems. Moreover, TECs do not use harmful refrigerants, making them an environmentally friendly option.

Air Conditioning: Thermoelectric air conditioning systems could offer an efficient alternative to traditional air conditioners, particularly in applications where space and weight are critical factors, such as in electric vehicles or aircraft.

Precision Temperature Control: TECs are ideal for applications requiring precise temperature control, such as in medical devices, laboratory equipment, and telecommunications. Their ability to quickly and accurately adjust temperature makes them valuable for maintaining the stability of sensitive instruments.

3. Wearable and Portable Thermoelectric Devices

The miniaturization and increased efficiency of thermoelectric materials have opened up new possibilities for wearable and portable devices that can generate power from body heat or environmental temperature differences.

Wearable Electronics: Thermoelectric generators embedded in clothing, wristbands, or other wearable accessories can harvest energy from body heat, powering small electronic devices such as fitness trackers, smartwatches, and health monitoring sensors. This technology could enable the development of self-powered wearables, reducing the need for frequent recharging or battery replacement.

Portable Chargers: Portable thermoelectric generators could be used to charge mobile phones, tablets, and other devices in remote or off-grid locations. By harnessing the temperature difference between a hot surface (such as a campfire) and the ambient environment, these devices could provide a reliable power source for outdoor enthusiasts, emergency responders, and military personnel.

Medical Devices: In the medical field, thermoelectric technology could be used to power implantable devices, such as pacemakers, by harvesting energy from the body's natural temperature gradients. This innovation could significantly extend the lifespan of these devices and reduce the need for invasive battery replacements.

4. Space Exploration and Remote Sensing

Thermoelectric technology has long been used in space exploration, where reliability and longevity are critical. Radioisotope thermoelectric generators (RTGs), which convert the heat released by the decay of radioactive materials into electricity, have powered numerous space missions, including the Voyager probes and the Mars rovers.

Deep Space Missions: In the future, thermoelectric technology will continue to play a crucial role in powering spacecraft on deep space missions. RTGs are particularly well-suited for environments where solar power is not viable, such as the outer reaches of the solar system or shadowed regions of the moon and asteroids.

Remote Sensing: Thermoelectric sensors can be used in remote and harsh environments, such as polar regions, deserts, and ocean floors, where conventional power sources may be unavailable or impractical. These sensors can operate autonomously for extended periods, collecting valuable data for climate research, environmental monitoring, and geological surveys.

5. Integration with Renewable Energy Sources

As the world shifts towards renewable energy, thermoelectric technology could play a complementary role in enhancing the efficiency and reliability of renewable energy systems.

Solar Thermoelectric Generators: Solar thermoelectric generators (STEGs) combine solar thermal energy with thermoelectric conversion, allowing them to generate electricity from both direct sunlight and ambient heat. Unlike traditional photovoltaic cells, which only work efficiently under direct sunlight, STEGs can continue to generate power even in diffuse light conditions, such as on cloudy days.

Geothermal Energy: Thermoelectric generators can be used to harness low-temperature geothermal resources that are not suitable for traditional geothermal power plants. By converting the heat from these resources directly into electricity, thermoelectric systems could unlock new geothermal energy potential in areas with lower heat flux.

Hybrid Energy Systems: Thermoelectric technology can also be integrated into hybrid energy systems that combine multiple renewable energy sources, such as solar, wind, and biomass. By capturing and converting waste heat from these systems, thermoelectrics can increase overall energy efficiency and provide a more stable and reliable power supply.

Innovations Driving the Future of Thermoelectrics

1. Advanced Materials and Nanotechnology

One of the most significant challenges in thermoelectric technology has been improving the efficiency of materials. Recent advances in material science, particularly in nanotechnology and low-dimensional materials, are driving significant improvements in thermoelectric performance.

Nanostructured Materials: Nanostructuring involves manipulating materials at the atomic or molecular scale to enhance their thermoelectric properties. By reducing thermal conductivity while maintaining or improving electrical conductivity, researchers have achieved higher ZT values. Materials such as nanocomposites, quantum dots, and superlattices are showing great promise in this area.

Topological Insulators: Topological insulators are a class of materials with an insulating interior but a conductive surface. These materials have been found to exhibit excellent thermoelectric properties, particularly at low temperatures, making them ideal for applications such as space exploration and cryogenics.

Flexible and Organic Thermoelectrics: Researchers are also exploring flexible and organic thermoelectric materials that can be integrated into wearable devices and flexible electronics. These materials, such as conductive polymers and hybrid organic-inorganic compounds, offer the potential for lightweight, low-cost, and environmentally friendly thermoelectric solutions.

2. 3D Printing and Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is opening up new possibilities for the design and production of thermoelectric devices. By allowing precise control over material composition and structure, 3D printing enables the creation of complex thermoelectric geometries previously impossible with traditional manufacturing techniques.

Customizable Designs: 3D printing allows for the customization of thermoelectric devices to meet specific application requirements. For example, it is possible to create thermoelectric modules with optimized shapes and sizes for integration into complex systems, such as automotive exhaust systems or wearable devices.

Cost-Effective Production: Additive manufacturing also offers the potential for cost-effective production of thermoelectric devices. By reducing material waste and enabling on-demand manufacturing, 3D printing could lower the production costs of thermoelectric systems, making them more accessible for a wider range of applications.

Integration with Other Technologies: 3D printing can facilitate the integration of thermoelectric materials with other advanced technologies, such as sensors, batteries, and microelectronics. This could lead to the development of multifunctional devices that combine energy harvesting, sensing, and data processing in a single platform.

3. AI and Machine Learning for Material Discovery

Artificial intelligence (AI) and machine learning are playing an increasingly important role in the discovery and optimization of new thermoelectric materials. By analyzing vast datasets of material properties and performance, AI algorithms can identify promising candidates for high-efficiency thermoelectrics and predict how they will behave under different conditions.

Accelerated Material Discovery: Traditional methods of discovering and testing new materials can be time-consuming and costly. AI-driven approaches, such as generative design and predictive modeling, can accelerate the discovery process by identifying the most promising materials and optimizing their properties before they are synthesized and tested in the lab.

Optimization of Manufacturing Processes: AI can also be used to optimize the manufacturing processes for thermoelectric devices. By analyzing data from production lines and simulations, machine learning algorithms can identify ways to improve the efficiency and consistency of the manufacturing process, reducing defects and increasing yields.

Real-Time Performance Monitoring: Once thermoelectric devices are deployed, AI can be used to monitor their performance in real-time, identifying any issues or inefficiencies and providing recommendations for adjustments or maintenance. This could lead to more reliable and efficient thermoelectric systems in the field.

Challenges and Considerations for the Future

1. Cost and Scalability

One of the primary challenges facing the widespread adoption of thermoelectric technology is cost. High-performance thermoelectric materials are often expensive and difficult to produce at scale. Overcoming this barrier will require advances in material synthesis, manufacturing processes, and economies of scale.

Material Availability: Some of the most efficient thermoelectric materials, such as bismuth telluride, contain rare or toxic elements, which can limit their availability and increase costs. Developing alternative materials that are more abundant and environmentally friendly will be crucial for the future of thermoelectrics.

Manufacturing Innovations: Reducing the cost of thermoelectric devices will also require innovations in manufacturing. Techniques such as 3D printing, roll-to-roll processing, and solution-based synthesis could lower production costs and enable large-scale manufacturing of thermoelectric systems.

2. Integration with Existing Technologies

Another challenge is integrating thermoelectric systems with existing technologies and infrastructure. For example, retrofitting industrial facilities or vehicles with thermoelectric generators may require significant modifications, which can be costly and complex.

System Compatibility: Ensuring compatibility with existing systems, such as HVAC, automotive, and power generation infrastructure, will be essential for the successful deployment of thermoelectric technology. This may involve developing standardized modules and interfaces that can be easily integrated into a wide range of applications.

Interdisciplinary Collaboration: The successful integration of thermoelectrics will also require collaboration across multiple disciplines, including material science, engineering, electronics, and data science. Bringing together experts from these fields will be key to overcoming the technical challenges and realizing the full potential of thermoelectric technology.

3. Environmental Impact

While thermoelectrics offer potential environmental benefits, such as reducing greenhouse gas emissions and improving energy efficiency, there are also potential environmental concerns that need to be addressed.

Material Toxicity: Some thermoelectric materials contain toxic elements, such as lead or cadmium, which can pose environmental and health risks if not properly managed. Developing alternative materials that are both efficient and environmentally friendly will be crucial for the sustainable growth of thermoelectric technology.

End-of-Life Management: The disposal and recycling of thermoelectric devices must also be considered to minimize their environmental impact. Developing processes for the safe and efficient recycling of thermoelectric materials will be important for reducing waste and conserving resources.

Conclusion: The Bright Future of Thermoelectrics

The future of thermoelectrics is full of promise, with potential applications ranging from waste heat recovery and renewable energy integration to wearable electronics and space exploration. As advances in material science, manufacturing, and AI continue to drive innovation in this field, thermoelectric technology is poised to play a critical role in the global transition to a more sustainable and energy-efficient future.

However, realizing the full potential of thermoelectrics will require overcoming several challenges, including improving material efficiency, reducing costs, and ensuring environmental sustainability. By addressing these challenges and continuing to explore new applications, thermoelectrics could become a cornerstone of the next generation of energy and technology solutions.

What potential do you see for thermoelectric technology in your industry? Email us at das@academicworld.co.uk